2 shows a portion of a finite element model for a semiconductor die blue bonded to. Experienced vendors also apply a very small amount of gold-tin solder to the packages that interface with the heat sinksspreaders.

Why Gold Tin Is The Best Solder Alloy

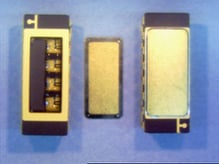

AuSn-preforms die-attach application is becoming the preferred method for the assembly of high power laser diodes LD as seen in Figure 4.

Gold tin mixture for die attach. This equipment is capable of handling the complete die-attach process including high-accuracy. For years people have been using gold-tin in high-temperature applications but we have the ongoing problem of voiding. Eutectic gold-tin Au80Sn20 is widely used as the die-attach material for making RF and microwave devices due to its superior thermal and mechanical properties good compatibility with the gold metallization surface and a relatively high melting temperature 280C to prevent thermal fatigue.

Die attach alloys with different loadings of tin 20 30 40wt on AlN ceramic substrates for high temperature use. Gold-Tin Solder Offering Gold-tin solder systems are employed in hybrid microelectronic applications for the mounting of semiconductor die to the parent circuit. Resistant to alkaline corrosion.

With gold and a common eutectic solder alloy for die-attach is gold-tin AuSn 8020. Gold Tin Facts 80au20sn 40000 PSI shear strength. Its not just high-temperature appli.

Automated eutectic attachment is a leading technique for high-performance and high-capacity die attach applications. The LD chips are bonded by AuSn preforms onto heat sinks which are usually made of copper. When sintering at 220 C the die-shear strength is only about 5 MPa which is due to non-densification sintering at low temperature as shown in Fig.

The two elements mix together to form an alloy. Several bonding processes are available on Infotech systems - EutecticThermo-Compression Bonding Sintering UV Curing Ovens Bottom Heaters Ultrasonic Bon. 7 illustrates the structure built for the paper.

AuSn demonstrates good compatibility with gold-based devices and also demonstrates excellent long-term reliability. The suggested solder preforms are eutectic gold-tin and may be implemented for high volume or lab quantity adoption using a Palomar Technologies die bonder. Solder preforms of a precise size and thickness are commonly used during eutectic die-attach to ensure consistency of the die-attach process.

For use as a die-attach material in high power devices. To accomplish both a thermally enhanced package with an extremely flat die attach surface was created and a revolutionary gold-tin AuSn eutectic die attach process using. Tight dimensional tolerances ensure repeatable solder volume.

Gold Preforms and Ribbon. 278C melting point eutectic Excellent thermal fatigue properties. Array Solders manufactures gold preforms used in die attach and hermetic sealing applications.

The die is then placed with controlled force over the preform using a collet and the. Gold tin solder may be sputtered in selected areas of a circuit to facilitate component attachment. Request PDF Reliability optimization of gold-tin eutectic die attach layer in HEMT package This paper compared the fatigue damage accumulation of the gold-tin eutectic die attach layer in.

Optimize the die-attach assembly technique to maximize thermal dissipation. The needs of the current industry environment with high-volume and high-placement accuracy 5 micronsclearly call for flexible. For die-attach using the trimodal-silver paste the shear strengths first increase and then decrease with temperature.

High thermal conductivity 057 WcmC 85C. In electronics packaging the term Eutectic die attach originally referred to 97 Gold 3 Silicon which forms naturally when pure Silicon is heated in contact with a clean Gold plated surface ie. The preform such as gold-tin or gold-germanium alloy is placed on the heated substrate using a pickup tool.

NexLogic Technologies For example pure gold has a very high melting point temperature of over 1000C while silicon melts at over 1400C. Maximum average shear strength above 40 MPa was achieved when sintering at 270 C. Also called flux-less solder attach eutectic die attach uses a thin metal layer called a preform.

For areas within the substrate perimeter allow a 0003 inch 0076. Size of the die attach pad relative to die size and the shape of the die attach fillet Thickness of the die attach paddle this determines how much bending of the paddle occurs during die attach Fig. Tiny solid shapes from 0152mm 0006 High aspect ratio and complex special shapes.

Loy is the eutectic which for the Lead Tin sys-tem is 63 Tin 37 Lead. NC-SMQ75 is the only solder paste suitable for use in non-cleaned clip bonded applications in power semiconductor die-attach assemblies. A typical eutectic die bonding process begins with the placement of the substrate to the hot plate or bonding site using a flat-faced pickup tool.

Since the efficiency of a LD will drop dramatically with increasing temperature conducting heat away from the LD is. Thickness from 00127mm 000035 and greater. The next step is bringing the substrate and die together and then applying the proper temperature profile in an inert gas environmentpossibly scrubbing the interface under a specific force and cooling the eutectic media back down to its plastic or solid point before final release.

Flatness measurement capabilities to 000254mm 00001 Large die library with in-house tooling capabilities. It is designed for reflow in a nitrogen or forming gas atmosphere of 100 ppm oxygen or less and can survive the high temperatures associated with both high-lead Pb and gold-tin alloy reflow.

Vintage Coke Tin Can Collectible With Handle Walmart Com Vintage Coke Coke Drink Tin Can

Tidak ada komentar