Solenoid Valve will be open until 200 gal has poured in. The combined blowing process uses expensive gases O2 Ar and N2 and the accurate measurement and totalization of these gases assist the economic operation and the tight quality control by using these values in the generation of daily reports for management control.

Other gases like CO CO 2 H 2 Ar or He do not affect the sensor but are added to the total nitrogen percentage as they are not O 2.

N2 gas control using plc in tin bath. 4 using touch screen And PLC human-computer interaction system to achieve intelligent production and control. The Ventis-MX4 portable gas detector can detect up to 4 gases amongst explosive gases oxygen O2 carbon monoxide CO hydrogen sulfide H2S sulfur dioxide SO2 and nitrogen dioxide NO2. You obviously can keep and breed fish successfully using microbe only filtration but it is a system with a single point of failure the filter and very little resilience.

Basic parameter of Model YX-45AA tobacco cans vacuum seaming machine semi automatic metal tin sealing closing capping equipment. Portable N2 gas detector pump suction type suitable for Nitrogen gas leakage detection with 0 to 100 Vol measuring range and give an alarm with sound light and vibration. To stir the converter bath Ar or N2 gas is injected through a number of.

The flow meter gives one pulse for every gallon of flow. Workers in these areas often use gas monitors to warn of excessive gas con-centrations and to help them determine when to increase ventilation air that will dilute these gases thus minimizing exposures to this gas. Light compact Nitrogen gas detector high accuracy fast response and good cost performance.

High and low flow drain valves are incorporated for precise draining. Nitrogen is a carrier gas in gas chromatography for various industrial and hospital analyses and quality control. Inverter Constant Pressure Control 99 150 050 999 102 539 53 9999 69 kW Output 5060Hz Compressor 055 055 N 2 Pack Vtype 3755 N 2 Pack 22 m3h MPa mm kg dBA ItemUnit Model Nitrogen Gas Purity1 Nitrogen Gas Capacity2 3 Nitrogen Gas Discharge Pressure Nitrogen Gas Discharge Port Ambient Temperature.

In the gas lines remember all of the gas line up to the normally open hardware interlock nupro valve is incorporated in the chamber vacuum and needs to de-gas at the end of a long clean run. The inert gas plant includes an inert gas generator a scrubbing tower unit two centrifugal fans an effluent water seal a fuel injection unit an intermediate dryer unit refrigeration type a final dryer unit adsorption type together with an instrumentation control system. The rest was up.

Inert gas is produced by the combustion of gas oil supplied by. Includes N2 IPA Dispersion manifold in automated lid. Nitrogen N2 - Dinitrogen - UN1066 UN1977 - 7727-37-9.

We have collaborations with European and North American leaders for hydrogen production using these hydrocarbons and offer their cutting edge technology to customers in India. Nitrogen creates a reductive atmosphere over the tin bath in glass production process. Wait 30 minutes before running a deposition process using silane after finishing a clean.

Most gas detection systems provide alarm contacts only. A specific location is dedicated to the explo sensor catalytic sensor and the oxygen sensor electrochemical sensor. PLC Control System- Graphical touchscreen interface allows for ease of use and continuous feedback of all major functions as well as a digital IO interface for all functional components.

Axcel Gases is a renowned Nitrogen gas manufacturer supplier and exporters both in liquid and compressed gas forms. Nitrogen Gas is tasteless odorless colorless and nonflammable gas present in atmosphere at a concentration of 7809 by volume. COMBINATION GAS CONTROLS By.

Using the ideal gas relation the specific volume and the mass flow rate of air are determined to be 04525 m kg 300 kPa 0287 kPa m kg K473 K 3 3 1 1 1 P RT v V 0008m 30ms 05304 kgs 04525m kg 1 1 2 1 1 3 1 A v m b We take nozzle as the system which is a control volume since mass crosses the boundary. This feature allows you to use certain FX-PC controllers as field replacements for legacy Metasys or Facility Explorer branded N2 controllers hereafter referred to as legacy N2 controllers. About 2 million new gas furnaces and approximately 150000 gas boilers are.

It is also a balance gas of the calibration gas mixtures for environmental. Small particles less than 5um which appear in concentrated. Released by these processes.

It has a boiling point of. The term retroreflective devices as used herein being intended to encompass generally optical components used for returning radiation automatically from a remote location toward an optical source. 2 IntroductionASC and N2 Bus Networking and Troubleshooting Guide Metasys Installation Practices Page 33 Quiet Wiring vs.

Many of these legacy N2 controllers are no longer in production making direct replacement no longer feasible. This panel mount version is designed to mount flush on a compressor control panel or other flat surface. After ingredient A is in the tank 200 gal of ingredient B should be added.

Noisy Wiring 33 Using Enclosures for ASCs 33 Hard and Soft Grounding 33 Using Shielded Cable in Noisy Environments 34 Sample Installations with Shielded Cable 36 Suppression Devices 39 Summary of Installation Practices 41. This invention relates to retroreflective devices and systems incorporating such devices. Cole Honeywell INTRODUCTION Gas is the most popular fuel for heating homes in America.

Portable gas monitors used to measure NO 2 levels must be calibrated before each use. And anaerobic de-nitrification of NO3- and out-gassing N2 gas. Well over 40 million homes across the country use gas as their source of heat.

In one aspect an embodiment of the invention is a retroreflective device comprising a lens having a. Using methanol naphtha and natural gas is suitable for high flow and high purity production of hydrogen. Suppose for example that you wanted to control fans in a parking garage using CO concentration and time of day and preferred that the CO control be based on evaluating conditions at several sample points simultaneously.

In conclusion as the N 2 content in the gas discharge guides the nitrogen composition it is the key parameter in colour control for TiN x sputtered films especially when N 2 mass flow is less. The process of adding follows the same procedure as ingredient A. The Nuvair Pro N 2 Alarm analyzer measures nitrogen N 2 levels in gases in the range of 00 to 100 by calculating the lack of oxygen O 2 in mixed gases.

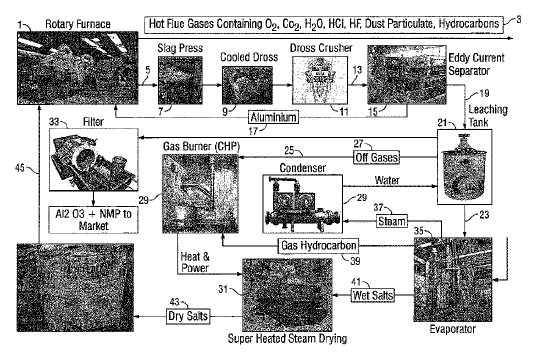

Aluminum Remelting And Casthouse Strategies Light Metal Age Magazine

Tidak ada komentar